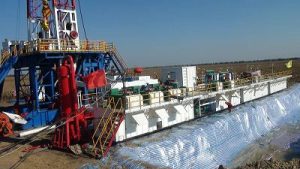

Hace varios meses, un cliente ordenó que la centrífuga decantadora y las bombas centrífugas del control de sólidos GN, y ahora la unidad de centrífugas están trabajando en su lugar de trabajo en Canadá para el tratamiento de lodos de petróleo. El lodo de petróleo provendría del sitio de perforación, los recortes de desechos oleosos, el tanque de almacenamiento de petróleo, la suspensión de lavado de sedimentación en el fondo y la planta de refinería, los desechos oleosos.

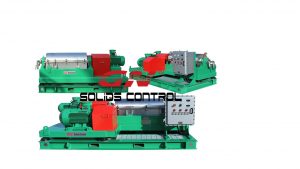

GN tiene una centrífuga decantadora diseñada especialmente para la industria petrolera. Después de algunos años de desarrollo, la unidad de centrífuga fue aprobada calificada para el control de sólidos, la separación de sólidos finos, el reciclado de fluidos de perforación y la recuperación de aceite del lodo oleoso residual.

Antes de la centrífuga decantadora, el cliente ya tenía la unidad de agitación para la separación de sólidos gruesos. Este lodo aceitoso espeso se mezclaría con productos químicos en primer lugar en un tanque de acero para la demulsificación y la reducción de la viscosidad. Pero solo con la unidad de agitación no se pueden eliminar los sólidos finos en la suspensión. Después de una comunicación suficiente y visitas a la fábrica, el cliente conoce completamente la capacidad de la centrífuga de decantación de GN, y finalmente ordenan dos unidades de GN.

Una de las dos centrífugas es de 14 pulgadas con una velocidad máxima de hasta 3900 RPM. Este es el modelo más popular de GN para la industria petrolera. Con una alta velocidad, esta unidad puede eliminar los sólidos ultrafinos de la lechada si se agrega un agente de floculación. La otra unidad solicitada es la centrífuga de taza grande de GN con un tazón de rotación de 22 pulgadas de diámetro; esta unidad se usa para eliminar los sólidos de gran contenido debido a su gran capacidad de flujo.

Poco antes, GN mejoró el material de la taza de la centrífuga al usar acero inoxidable de 2304 con características mucho mejores sobre la resistencia a la corrosión. La tecnología de fundición centrífuga hace que el cuerpo del recipiente tenga un mejor rendimiento de equilibrio. Ambas unidades están equipadas con panel de control VFD para varias condiciones de trabajo y múltiples propósitos del cliente. GN también puede proporcionar el patín para centrífuga para obtener un rendimiento conveniente.