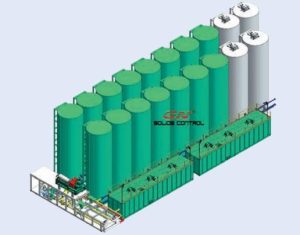

GN Solids Control is proud to announce its recent collaboration with an Oman-based project, supplying cutting-edge equipment tailored to their specific needs. The project, situated in Oman, required advanced solids control solutions to enhance efficiency and productivity in drilling operations.

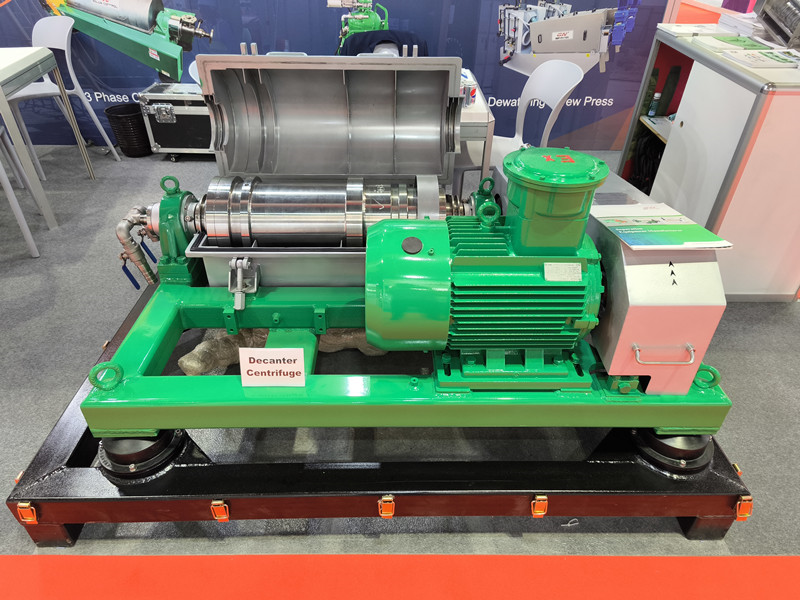

Among the key equipment provided by GN Solids Control are the High G Drying Shaker and the Decanter Centrifuge. These two components play pivotal roles in the solids control process, ensuring optimal separation and management of drilling fluids.

The High G Drying Shaker, equipped with a spiral conveyor funnel, is designed to efficiently remove excess moisture from drilling cuttings, facilitating their disposal and minimizing environmental impact. Its robust construction and high G-force capabilities make it an ideal choice for demanding drilling environments.

Complementing the High G Drying Shaker is the Decanter Centrifuge module, specifically the GNLW363D model. This centrifuge excels in separating fine solids from liquids, delivering clarified fluids ready for reuse in drilling operations. With its advanced design and precise engineering, the GNLW363D ensures consistent performance and reliability in the most challenging conditions.

GN Solids Control’s commitment to innovation and customer satisfaction is evident in the design and functionality of these equipment modules. Each component is meticulously crafted to meet the rigorous demands of the drilling industry while offering enhanced efficiency and cost-effectiveness.

As the Oman project progresses, GN Solids Control remains dedicated to providing unparalleled support and expertise to ensure the seamless operation of their equipment. With a focus on delivering superior performance and reliability, GN Solids Control continues to set the standard for excellence in solids control solutions.

For more information about GN Solids Control’s High G Drying Shaker and Decanter Centrifuge modules, please visit our website or contact our sales team directly. We look forward to serving your solids control needs and contributing to the success of your projects.