In the realm of industrial processes, efficiency and safety are paramount. One area that often requires meticulous attention is tank cleaning. Tanks used in various industries such as oil and gas, chemical, and food processing often accumulate residues, sludge, and sediments that can hamper operations and compromise product quality. Enter the GN Solids Control Tank Cleaning System – a cutting-edge solution that is revolutionizing the way industries approach tank cleaning.

Traditional tank cleaning methods are not only time-consuming but can also pose significant safety and environmental risks. Manual cleaning, involving personnel entry into confined spaces, can lead to accidents, exposure to hazardous materials, and production downtime. Moreover, these methods are often inefficient, leaving behind traces of residues that can contaminate subsequent batches or cause equipment corrosion.

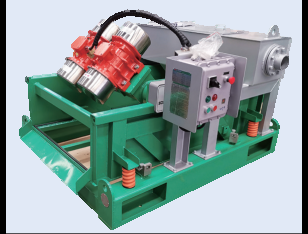

The GN Solids Control Tank Cleaning System addresses these challenges by offering a comprehensive, automated, and environmentally friendly approach to tank cleaning. This innovative system utilizes advanced technologies to ensure thorough cleaning, reduced downtime, and enhanced safety.

One of the standout features of the GN Solids Control system is its closed-loop design. This means that the entire cleaning process occurs within a sealed environment, minimizing the release of harmful vapors or emissions into the atmosphere. Closed-loop cleaning not only protects workers but also prevents cross-contamination and adheres to stringent environmental regulations.

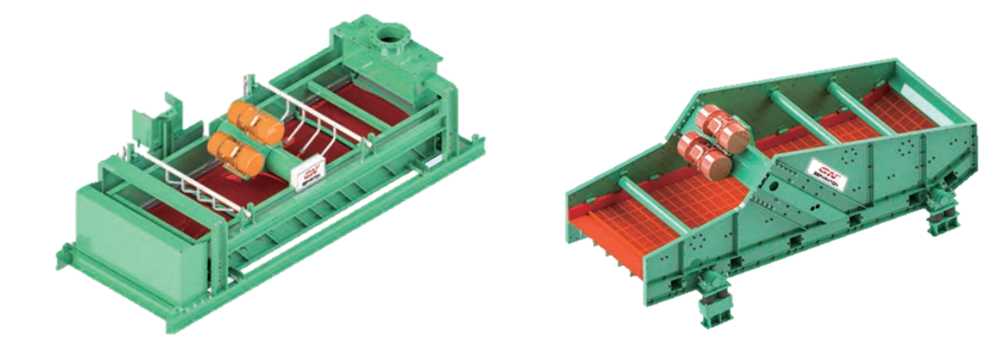

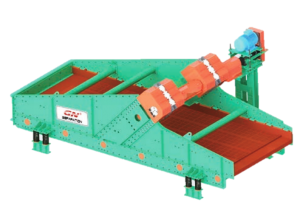

The system is equipped with advanced solids control equipment that separates solids from liquids during the cleaning process. This results in cleaner, reusable liquids and reduces waste disposal costs.

The system’s design allows it to be adapted for various tank sizes, shapes, and industries. From large storage tanks to compact reactors, the GN Tank Cleaning System can be customized to meet specific cleaning requirements.