In the ever-evolving world of drilling and exploration, efficiency, safety, and environmental considerations are paramount. GN Solids Control, a global leader in providing solids control and separation equipment, has introduced a groundbreaking solution that promises to revolutionize drilling operations – Mud Guns. In this blog, we will delve into what Mud Guns are, their significance in drilling processes, and how GN Solids Control is shaping the industry with their innovative approach.

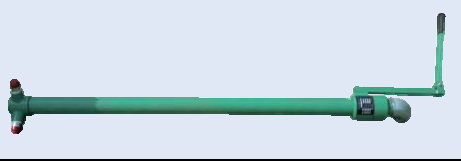

Mud Guns are essential components of drilling mud systems, designed to agitate, mix, and suspend drilling fluids in order to maintain homogeneity and prevent solids from settling. These guns are typically mounted on the mud tanks and equipped with nozzles that can rotate and direct high-velocity mud streams. Mud Guns play a crucial role in preventing solids from settling at the bottom of the tank, which can lead to various issues such as decreased drilling efficiency, increased wear and tear on equipment, and even wellbore instability.

The primary purpose of Mud Guns is to keep the drilling fluids well-mixed, ensuring that any drilled cuttings or solids are suspended evenly throughout the mixture. This prevents the formation of a solid layer at the tank bottom. Settled solids can cause excessive wear and tear on drilling equipment, leading to increased maintenance costs and downtime. By using Mud Guns, operators can extend the lifespan of their equipment.

Homogeneous drilling fluids lead to enhanced drilling efficiency. Smoothly flowing mud reduces friction, increases cooling, and aids in transporting cuttings to the surface. Unwanted solids settling at the bottom can potentially affect wellbore stability. By maintaining proper mud consistency, Mud Guns contribute to maintaining well integrity.