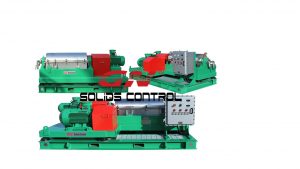

GN Solids Control tiene una amplia gama de centrífugas decantadoras de 9 pulgadas a 30 pulgadas, la longitud del tazón y la proporción de diámetro es de hasta 4.2 para aplicaciones diferenciales. Este proyecto, que está listo para su envío, es una gran centrífuga decantadora de 22 pulgadas con unidad de dosificación de polímero en un contenedor de 20 pies para el tratamiento de aguas residuales industriales.

Centrifugadora de aguas residuales

En este proyecto de tratamiento de aguas residuales, los clientes solicitaron la centrífuga decantadora de 22 pulgadas, la bomba de tornillo para la alimentación de la centrífuga y un sistema de dosificación de polímero de 20 pies. La centrífuga GNLW553C-VFD es una centrífuga de tazón de 22 pulgadas con una longitud de tazón de 71 pulgadas. El tamaño del tazón es de hasta 2800 RPM con los paneles de control VFD y HMI. La tecnología química mejorada es capaz de proporcionar a las soluciones de aguas residuales una separación de cero puntos de corte para descargar el agua limpia.

Unidad de dosificación de polímeros

Ventaja de GN centrífuga de tratamiento de aguas residuales

1) Cuenco ajustable y velocidad diferencial para diferentes aguas residuales.

2) Continuar la operación con menos poder humano.

3) Menos huella que los filtros de prensa.

4) Menos consumo de polímero que los filtros de prensa.

5) Protección de las baldosas de carburo de tungsteno para prolongar la vida útil de la centrífuga con menos mantenimiento.

6) Socios de distribución y sucursales en todo el mundo para brindarle soporte local.