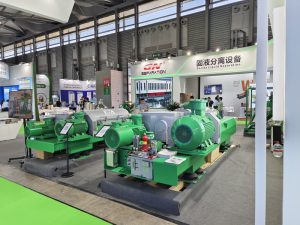

At the Offshore Technology Conference (OTC) 2025 in Houston, GN Solids America once again proved its commitment to providing field-ready solutions for the oil & gas and environmental sectors. The company’s booth attracted significant attention from operators, service providers, and environmental consultants looking for compact, reliable, and cost-effective separation equipment.

A major highlight at the booth was the GNLW223D Decanter Centrifuge, a compact 9-inch unit tailored for projects where space and capacity are limited but performance cannot be compromised. Whether it’s for small-scale tank cleaning, offshore pilot projects, or core drilling fluid recycling, the GNLW223D offers impressive dewatering and clarification capabilities. With a bowl speed up to 4500 RPM and VFD control, users can fine-tune operations for maximum efficiency.

GN also showcased its GNSP-10B vacuum pump, designed to transfer drilling waste, oil sludge, or tank bottom residue over long distances—without using electricity. The pump’s air-driven, explosion-proof design makes it ideal for hazardous zone operations, such as offshore platforms or remote oilfields. Its simple yet durable construction ensures minimal maintenance and reliable performance in the toughest conditions.

The GNZS series shale shaker, displayed alongside, caught the eye of many mud engineers and drilling supervisors. Known for its high G-force linear motion and composite screens, it offers effective primary solids control to protect downstream equipment and extend fluid life.

What resonated most with visitors was GN Solids America’s practical approach: modular designs, real inventory in Houston, and responsive service backed by engineering expertise from GN’s global team. Many customers appreciated the ability to scale up from lab-sized units like GNLW223D to full systems for large oilfield or environmental projects.

Our team was excited to meet with clients from the U.S., Latin America, Canada, and beyond, many of whom were looking for local support, fast delivery, and a trustworthy partner in solids control. GN Solids America’s Houston warehouse, technical service team, and inventory of spare parts make us uniquely positioned to serve these needs with minimal lead time.

Participating in OTC 2025 not only strengthened our brand visibility but also provided valuable feedback from end users and industry experts. It reaffirmed our mission to keep innovating and to support our partners in the oil & gas, mining, construction, and environmental sectors.

We extend our gratitude to everyone who visited our booth and shared their insights and requirements. The GN team looks forward to continuing these conversations and building successful partnerships in the months ahead.

For more information about our products and services in North and South America, please feel free to contact us in anytime.